Contents:

Types of cartons for packing and shipping parcels. Overview with discussion.

Do you manufacture, transport, sell or simply run another business that requires you to take special care of the processes involved in packing and transporting goods? Then you are surely wondering which cartons will allow you to speed up certain activities, improve the ergonomics of your work and, most importantly, reduce the losses associated with inadequate storage and shipment of parcels. Is that right?

Read on to learn about the tasks and the different types of cardboard boxes, and then find out which ones will work for your business.

What are and what roles do cartons play in packaging and shipping goods?

Cartons are boxes usually made of cardboard, which – depending on the specifics, the materials used and the industry itself – can take on the widest variety of sizes and forms. The overriding feature of each (properly selected cardboard box) is, of course, to protect its contents from damage, dirt and even loss. In addition, this type of solution also works well for keeping things tidy (both in the warehouse and directly in the vehicle).

It is due to these factors that they are used as much by manufacturing and transport companies as by companies selling a variety of products.

Types of cardboard boxes, i.e. which solutions work well for packaging and shipping parcels?

Cardboard boxes used for packaging can be divided according to several criteria, which include: the type of raw material used, the size, as well as the way they are folded.

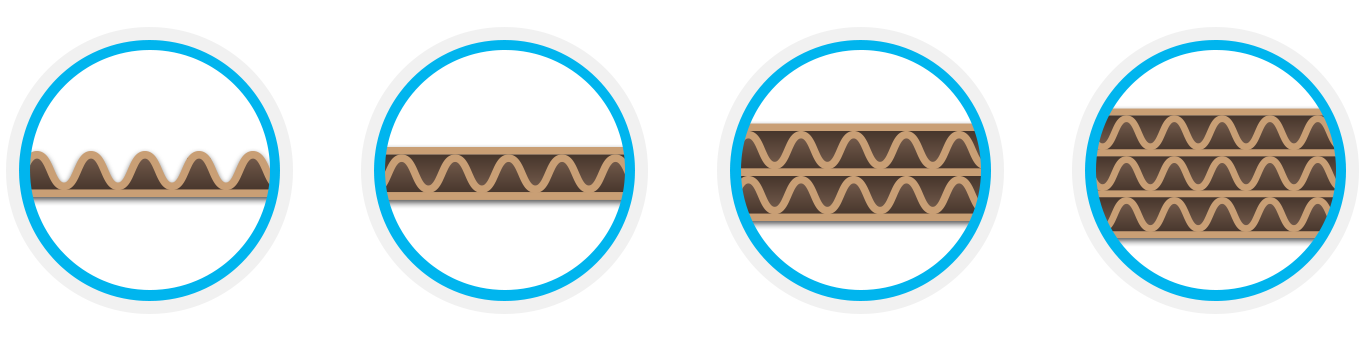

In the first group, therefore, we distinguish between two-, three-, five- and even seven-layer cardboard, which can be from 2.5 to as much as 7 mm thick, and whose grammage can range from 330 to nearly 1,500 g per square metre. Obviously, the higher the thickness and grammage parameters, the better the strength and stiffness of this type of element as well.

- Two-ply cardboard boxes are characterised by their flexibility and relatively low strength. They are therefore worth using for packaging goods that do not require special protection (especially against mechanical damage).

- Cartons made of three-layer cardboard have additional corrugated layers, which are suitable for transporting more demanding packages (among other things, they are responsible for cushioning).

- Cartons made of five- and seven-layer cardboard, on the other hand, are very robust solutions that are able to protect even the most delicate goods.

Types of cardboard boxes according to the way they are folded

In this area, however, we can mention three main product groups, namely cartons:

- Flap boxes, which come in many variants of designs and shapes, and their special feature are the so-called flaps for opening and closing this type of box. They are characterised by their high degree of versatility, ease of handling (folding and eventual unfolding) and relatively low resistance to damage.

- Shaped can be made in a variety of sizes and shapes to suit the contents to be transported. Their advantages include the fact that they are usually made to measure and, in addition, their folding is quick and efficient (no gluing required).

- Laminated, which, due to their hardened construction, are characterised by very high strength. They are ideal for securing and transporting heavy and large items and offer relatively high resistance to weather conditions (especially humidity).

How do I choose the right carton for packing and shipping parcels?

In order to decide which type of cardboard box is right for your business, you need to answer the question at the outset: what products are you going to pack and ship?

- If you are packing items that are not too susceptible to damage during transport (books, clothing, footwear, etc.) – you can successfully rely on flap cartons with a small thickness.

- If you are shipping relatively fragile electronic devices – the right choice will probably be suitably matched (in terms of thickness and weight) shaped cardboard boxes.

- If you sell and deliver furniture on a daily basis – thick and robust laminated cardboard boxes may be the best solution.

Do you want to improve the efficiency of packing and shipping cartons in your company?

You already know which cartons will be the best solution for your business and are therefore looking for additional ways to make your processes faster and more efficient? Professional parcel packing tables, warehouse trolleys, racks, as well as a wide range of other accessories may be the answer to your needs. Check out the extensive effepack assortment and if you want to ask a question – contact our experts, who will be happy to provide you with professional support.

Featured articles:

The e-commerce market. Opportunities and threats.

Over the past decade, the e-commerce market has undergone a tremendous transformation. Initially, sellers treated this type of activity merely...

Logistics 4.0 – a Difficult Challenge or an Opportunity for Growth?

The concept of "logistics" emerged a long time ago, around the 10th century. Initially, it was used exclusively in a...

Ecology tendencies in packaging parcels.

The disruption caused by the pandemic prompted specialists to reexamine this topic. In April 2021, the Mobile Institute conducted a...

Warehouse robots as part of logistics processes.

The basis for the automation of logistics processes in the warehouse and their efficient running is both the use of...

Envelopes. Types and their use.

At first association, an envelope is a paper package used to send letters or other flat items using postal mail....

Leave a Reply