How to pack parcels? 5 rules of effective packaging

Every online shop owner knows how difficult, time-consuming and costly the packaging process is. Unfortunately, it is unavoidable. After all, the product needs to be adequately protected against damage in transit, but the form of packaging itself has a significant impact on how buyers perceive us. Just read the reviews written after purchases, where the most frequently rated aspects are speed of delivery, contact with the seller and just the protection. This aspect is therefore extremely important for both us and our customers. How can we do this well without going bankrupt?

In this guide, we will give you the 5 most important rules that you simply must take into account.

Rule 1: External packaging

It is this element that is the first and most important protection for your products on their way to the customer. Their durability can guarantee your success or failure. The most common packaging used for shipping products are cardboard boxes, envelopes and foil packs.

Envelopes, whether regular or bubble envelopes or foil envelopes, are used for products that are very sturdy, as well as small and lightweight. They do not provide good protection. The product which we put in them must have its own protection, e.g. in the form of a rigid blister, carton or box. Their use is more a form of necessity due to the requirements of courier companies than a type of protection. This is due to their lack of resistance to bending or pressure. They are ideal if you are sending memory cards in a box, small electronics in strong blisters or clothes.

Cartons are the most versatile form of packaging due to their shape and range of sizes. Of course, their cost is significantly higher than that of envelopes or foil packs, which is why they are not the best choice in every case. They are ideal for products that require greater protection, but also in situations, for example, where several items are sent to one recipient.

There is a huge cross-section of cardboard available on the market. We can choose from many sizes, weights, types or colours. We have already touched on this in our other article, where you will find a detailed explanation – CLICK to go to it.

Rule 2: Filling

The filling is designed to directly protect the product from damage. It fills the free space in the carton / envelope, does not allow the product to move and provides cushioning in case of falls.

The most commonly used filling materials are:

- Bubble wrap – an extremely universal and popular material. It enables both the wrapping of the products themselves and additional filling of the spaces inside the carton / envelope / foil package. It adapts perfectly to the packaged product. It has excellent protective properties.

- Paper filling – due to the trend towards ecology in packaging, it is gaining in popularity, especially as it is not inferior to bubble wrap when used appropriately. It is mainly used for cardboard packaging. Its main use is to fill the space between the packaged product and the carton. If we do it right, i.e. lining the bottom, sides and top of the carton properly, we can achieve a really well protected shipment. There are several types of paper fillings to choose from. These include recycled paper, which we crumple using special feeders, cardboard filler produced from cardboard boxes, or notched paper.

- Air bags – they work in a similar way to paper, i.e. they do not wrap the product itself, but protect the space between the product and the carton. Their biggest disadvantage is the need for a special machine to inflate them. We receive the cushions in a flat, rolled-up form. Only when they are needed does the machine pump and seal them, so that the final product is a ready-made filling. This is a tremendous space-saver, but requires an additional financial outlay to purchase the machine.

- Skropak – is a relative novelty on the market. Its undoubted advantage is that it is completely biodegradable, so it is definitely environmentally friendly. In appearance, it resembles crisps. Like paper and cushions, it is used to fill empty spaces in a cardboard box. The downside of this solution is storage, as it takes up a lot of space.

Rule 3: Markings

Markings are a way of communicating to the carrier (in simple terms) what is in the consignment and how it must be handled. They usually come in the form of a sticker that you simply stick on. If there are fragile products in it, it is a good idea to use the marking “Caution Glass” or “Careful Glass”. In certain situations, we can also apply a sticker indicating, for example, the top of the consignment so that it is not rotated during transport. Unfortunately, warning stickers alone do not give us any guarantee that these remarks will be taken into account by, for example, couriers. Nevertheless, their application does not generate high costs and may bring measurable effects.

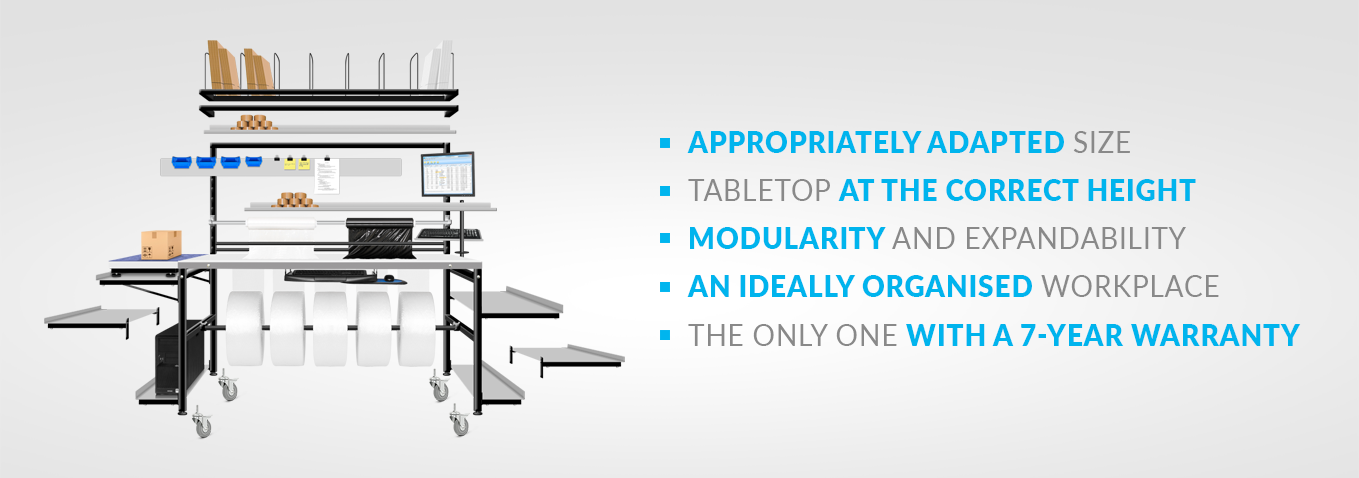

Rule 4: Workstation

A suitably adapted workstation is an extremely important part of the packaging process. With the use of a professional packing table, packing can be made faster and easier, the amount of filling material used can be reduced, work ergonomics can be increased and mistakes can be reduced.

The workstation must be ideally suited to our way of packing, the materials we use and the products we pack. It should include suitable shelves and handles. The elements must be adjustable in height. So that the most frequently used items are always within reach and at the right height. Packing then becomes much easier and lighter. The packers unintentionally do their work faster and with less fatigue.

What to look for before buying a professional packing table?

- Experience of the manufacturer – this really is extremely important. Would you want to drive a car manufactured by someone who is doing it for the first time and is just starting to learn the trade? Obviously, this is an exaggerated example, but specialists in the production of packaging stations have been doing this for years. They are refining their design. They know the answers to your questions and have completed so many projects that they are able to help you throughout the entire process of designing the perfect workstation. It is easy to verify such a manufacturer by references, realisations, browsing social networks, online reviews and, of course, by assessing the professionalism of the website, which must include all the most important product information but also articles or guides that give credence to the company’s knowledge.

- Modularity and expandability – modularity allows you to tailor the workstation to your needs and expectations. The parcel packing table can be configured a little like a car in a showroom. First you choose the size of the basic version (in the case of a car, the body version) and then the accessories (in the case of a car, the optional equipment) such as shelves or holders. The more accessories a manufacturer offers, the more customisation options we have and, consequently, the better our needs will be reflected. What is also important is that the table gives us the possibility to change it in the future. We cannot predict what will happen in a year, two or five (and a good table is a guarantee of many years of reliable operation). There may be changes in packaging processes, assortment or other aspects. In such cases, it is good to have a packing table that, without modifications, drilling and other complicated changes, will allow us to adapt quickly.

- Durability and guarantee – a good table is a reliable table. Simple. In reality, this can be very different. How to judge it? A table should have a stable steel construction with a minimum of bolted joints. Any place that is bolted is a potential place where play and vibration will occur, which we want to avoid. If the table you order is to come to you in a cardboard box, in the manner of Swedish shop furniture, this may be the first warning sign. Good packing tables usually arrive on a pallet mostly assembled. The customer is left with the ‘cosmetics’. A steel construction, of course, every table has. However, it all depends on what kind of construction it is. Is it lightweight, thin-walled, bent and perforated for strength or simply thick-walled, virtually indestructible profiles in normal use. We should also pay attention to the tabletop itself. Some materials are more durable others less so. In the case of wooden materials, splinters and other damage may occur when working directly on them with a knife, endangering both the products, the parcels and the person working on such a bench. An alternative is aluminium, which is not subject to such damage. Scratches may appear, but they are shallow and safe, even if you cut directly on it with a knife. Disadvantages: Higher price. It is a material that costs significantly more than wood-based materials and requires manual processing. Ultimately, such a table will simply be more expensive, but it is worth considering because it is an investment that lasts for years. The last aspect is the guarantee. Why do some manufacturers offer one year, others two years and still others seven years? As with any other product, the longer the guarantee period, the more secure we are, and the length of the guarantee offered may indicate how good the product is.

Rule 5: Advertising

Contrary to what you might think, there is still a lot you can do after delivery. There are plenty of ways to increase customer satisfaction, positively surprise them or persuade them to buy again / sign up for our newsletter or register for our online shop – just use the space in the parcel. What can you do? Some examples:

- Throw in a discount flyer for your next purchase or selected products.

- Add a freebie e.g. in the form of a keyring, stickers or other gadget.

- A sweet bonus? Why not. After all, you can add, for example, a fudge with your own logo to your delivery.

- Ask for a rating on a shop, auction site or Google business card.

- Offer a discount for joining a newsletter or registering with a shop.

As you can see, there are really many possibilities. It all depends on the type of customer or product you are selling. Look for non-standard solutions at your company and test them in practice.

Featured articles:

The e-commerce market. Opportunities and threats.

Over the past decade, the e-commerce market has undergone a tremendous transformation. Initially, sellers treated this type of activity merely...

Logistics 4.0 – a Difficult Challenge or an Opportunity for Growth?

The concept of "logistics" emerged a long time ago, around the 10th century. Initially, it was used exclusively in a...

Ecology tendencies in packaging parcels.

The disruption caused by the pandemic prompted specialists to reexamine this topic. In April 2021, the Mobile Institute conducted a...

Warehouse robots as part of logistics processes.

The basis for the automation of logistics processes in the warehouse and their efficient running is both the use of...

Envelopes. Types and their use.

At first association, an envelope is a paper package used to send letters or other flat items using postal mail....

Leave a Reply